WHY CHOOSE US?

MN Sons Lab Solutions provides a comprehensive range of customizable laboratory furniture engineered to support operational efficiency, user ergonomics, and environmental sustainability. Our solutions comply with international safety standards and are designed to meet the rigorous demands of modern laboratory environments. With extensive industry experience, we deliver precision-engineered furniture systems tailored for both new laboratory installations and the retrofit of existing facilities.

Our Services

We offer end-to-end laboratory solutions encompassing the design, manufacturing, and installation of fume hoods, laboratory furniture, and stand-alone units—custom-engineered to meet the demanding standards of industrial, scientific, and educational environments.Our expertise spans a wide spectrum—from heavy-duty industrial labs requiring high durability and chemical resistance, to modern educational institutions such as schools, colleges, and universities that need functional, safe, and student-friendly lab furniture.

-

Laboratory Furniture

We design and manufacture durable, ergonomic laboratory furniture tailored to meet the needs of modern research and industrial labs.

-

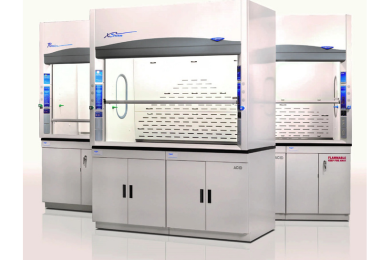

Laboratory Fume Hood

We specialize in manufacturing high-performance fume hoods designed for maximum safety and efficiency in laboratory environments.

-

Laboratory Stand Alone Units

Our stand-alone laboratory units offer flexible, space-saving solutions ideal for specialized tasks and compact lab setups.

-

"we would like to express our sincere appreciation to you for your seamless services for the supplies and installation of modular lab furniture for our various Laboratory as one of the most renowned service providers. Your team has been delivering high-quality work with exceptional customer service.

Owing to the impeccable delivery timing, troubleshooting techniques, and of course the level of post services provided by you, our Company has given you more contracts for the Lab of other units. Hope you’ll continue providing the quality of services you have been providing so far.

We would like to thank you again and look forward to working with you on coming projects for the years to come."Rakesh Baghel

Kutch Specialities Pvt. Ltd. (A unit of Kutch Chemicals) -

"Thanks to Kalpeshbhai and Team from M.N. Sons lab furniture for completing the R&D LAB and QC lab project, and their dedication to meeting project deadlines contributes to our team’s success. Your creativity has brought fresh ideas that have driven innovation within our lab.

Your flexibility in adapting to change has made a significant impact on completing our project in a timely manner.

Quality, price, and timely delivery are your great achievements."Dr.Muralidhar Shah

Vital Synthesis limited

Dahej

COMPANY OVERVIEW

MN SONS LAB SOLUTIONS offers fully in-house manufactured, high-quality lab furniture from our 10,000 sq. ft. facility in Vadodara.

We specialize in corrosion-resistant solutions tailored for chemical and industrial environments.

-

MN Sons Lab Solutions

An ISO 9001:2015 certified company who manufacture premium laboratory furniture, fume hood and its scrubber system. Formally we were known as ‘Scientific Lab’. Since, 2007 we have been manufacturing customised laboratory furniture addressing the distinctiveness of every lab. Our planning of lab furniture placement ensures that your laboratory have ergonomic work environment and our products are made durable enough to last against high corrosive atmosphere. We were Formerly known as Scientific Lab. And have been manufacturing lab furniture and fume hood for over the period of 20+ Years.

-

Manufacturing Unit

MN SONS LAB SOLUTIONS is a trusted name in laboratory furniture manufacturing, operating from a fully equipped, 10,000 sq. ft. in-house facility located in GIDC Makarpura, Vadodara. Our unit features advanced machinery including automatic bending machines, MIG and spot welders, a 7-tank pre-treatment plant, and a semi-automatic curing oven—ensuring precision at every stage of production.

We specialize in powder-coated lab furniture designed for durability and performance. Our products are tailored for harsh environments such as HCL, caustic soda, and HNO₃-based manufacturing units, offering superior resistance to corrosion and extending product lifespan. From bending to assembly, every component is manufactured in-house to deliver unmatched quality and reliability.

-

Our Services

We design and manufacture premium Laboratory Furniture, including workbenches, storage units, and island benches tailored to your lab needs.

Our Laboratory Fume Hoods ensure safe ventilation and protection in chemical handling environments.

We provide specialized Stand-Alone Units like reagent racks, sinks, and mobile trolleys for flexible lab setups.

Our Laboratory Utilities include gas lines, electrical fittings, and plumbing solutions integrated seamlessly into your lab infrastructure.

OUR MISSION

At MN Sons Lab Solutions, our mission is to deliver high-quality, innovative laboratory furniture and fume hoods that enhance the safety, efficiency, and comfort of laboratory environments. We are committed to providing our clients with tailored solutions that meet their specific needs while adhering to the highest industry standards. Through exceptional customer service and continuous improvement, we aim to foster long-lasting relationships with our clients, empowering them to achieve their goals in research and development.

Our vision is to be the leading manufacturer and supplier of laboratory furniture and fume hoods in the industry, recognized for our commitment to quality, safety, and sustainability. We aspire to transform laboratory spaces worldwide by integrating ergonomic design and eco-friendly practices into our products. By embracing innovation and collaboration, we aim to set new benchmarks in laboratory solutions, contributing to advancements in science and technology for a better future.

POPULAR QUESTIONS

-

What types of laboratory furniture do you offer?

We offer a wide range of laboratory furniture, including laboratory benches, storage cabinets, fume hoods, anti-vibration tables, and custom-designed solutions tailored to meet your specific needs.

-

How do I determine the right laboratory furniture for my space?

Our team of experts can assist you in evaluating your laboratory requirements. We consider factors such as available space, workflow, safety standards, and specific applications to recommend the most suitable furniture for your lab.

-

What is the installation process for your products?

Our installation process is straightforward and efficient. Once your order is confirmed, our skilled technicians will coordinate with you to schedule a convenient installation time. We ensure that all products are installed safely and according to industry standards.

-

Do you offer warranties on your products?

Yes, we stand behind the quality of our products. All our laboratory furniture and fume hoods come with a warranty that covers manufacturing defects and ensures peace of mind for our customers.

-

How can I maintain the laboratory furniture to ensure longevity?

To maintain the longevity of your laboratory furniture, we recommend regular cleaning with mild detergents, avoiding harsh chemicals that can damage surfaces. Additionally, periodic inspections for wear and tear will help identify any maintenance needs early on.